Team Ceramic Matrix Composites

Ceramic Matrix Composites

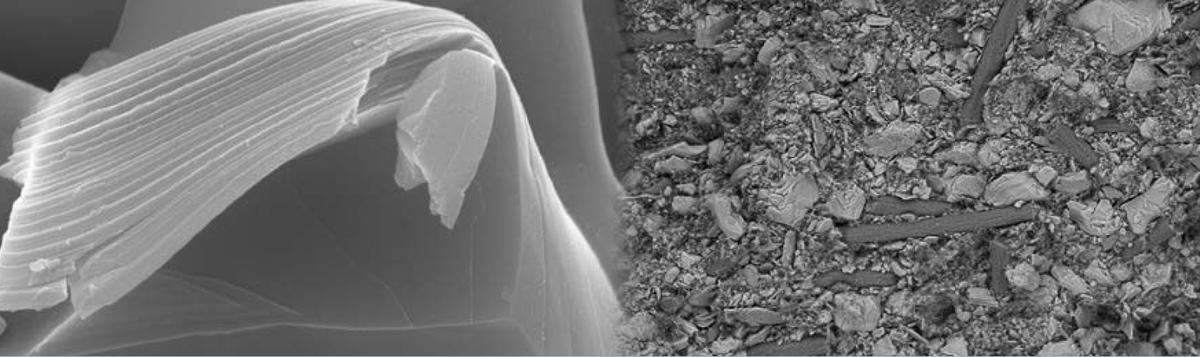

The team develops novel Ceramic Matrix Composites (CMCs) for systems that operate at high temperature and harsh environmental conditions, such as gas turbine components or Concentrated Solar Power (CSP) units. The composites are based on MAX phases as matrices, a novel family of materials that bridges the gap between ceramics and metals. Among all the MAX phases, we mainly focus on Cr2AlC, Ti3SiC2, Ti2AlC and Ti2AlN due to their excellent oxidation/corrosion resistance and good mechanical properties. Regarding the reinforcing phase, SiC and Al2O3 fibers are mainly used.

Processing Of Composites

The scope of the team includes the synthesis of MAX phase powders, processing of differentstructures and their densification. Pure MAX phase powders are obtained by two different synthesis routes: a novel process referenced as Molten Salt Shielded Synthesis (MS3) and by solid liquid state reaction. Scaling up these processes leads to kilograms of high-quality powder per batch, which is required to develop complex and large components as well as to facilitate the transferring of these new materials to industry. Based on our expertise in ceramic processing, we are able to develop different structures, from dense components and coatings by Thermal Spray Technologies as Cold Spray (CS) and High Velocity-Atmospheric Plasma Spray (HV-APS) to porous foams and near net shapes by Ceramic Injection Molding (CIM) and Additive Manufacturing (AM).

High Temperature Response

Developed CMCs are tested under realistic and aggressive environmental conditions, similar to those that the final components will withstand. Due to the novelty of MAX phases, their oxidation and corrosion resistance under different environmental conditions has not been explored sufficiently. Long term experiments at high temperature (1000 °C – 1300 °C) using burner rigs, thermal shock tests, characterization of the interaction of the CMCs with Thermal Barrier Coatings (TBCs), and mechanical characterization – flexural strength, tension and compression creep – are thus among the interests of the team.